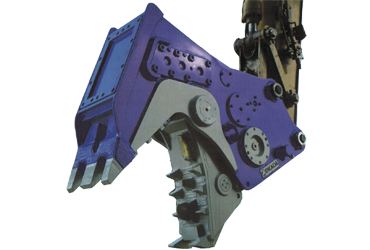

ATTACHMENTS /Crusher & Shear

Secondary Crusher

Combined with 77 years of experience, world class precision engineering and stringent quality control, Okada Aiyon Corporation has been to produce class leading hydraulic attachments.

Okada products are also renowned for their with their long product life and consistently high quality output, making them extremely popular in the used attachment market.

In addition to Okada’s technological expertise, the company continually innovates to expand the capabilities and versatility of their hydraulic attachments, so our clients can rest assured of the quality of our Okada’s attachment series.

Please visit our Catalog page under Parts & Services for the full product specifications.

A) OSC Series

Powerful and Efficient

-

Okada’s special geometric design allows cylinder output to be converted into strong crushing force in consistent manner with a short cycle time

-

Okada crushing teeth, made of wear resistant cast alloy, combines both pulverizing wedges and cutter blades to efficiently process reinforced concrete.

-

Class leading large jaw opening and larger crushing area to crusher more concrete at one go

Longer lasting

-

Standard built-in pressure relief valve protects the attachment against overloading.

-

Quality manufacturing process to ensure their crushers are lightweight and protected by a high tensile strength steel structure for excellent durability.

-

Cylinder rod are vital to crushers to operate properly. Okada crushers are equipped with cylinder rod protector and the location of the hydraulic cylinder in the crusher frame protects the cylinder rod from any exposure to concrete rubble.

B) ORC Series

Powerful and Efficient

-

The ORC series can function as both Primary or Secondary Crusher due to its built in rotary mechanism

-

Faster crushing speed with Okada’s unique speed valve, which utilizes return oil from the hydraulic cylinders to greatly increase the cycle speed of Okada’s crusher.

-

Cut easier with the reversible 180mm long cutter blades

Longer lasting

-

Unique double "shell shaped" wedges frame made with Hardox 400 steel, one of the hardest material in the world

-

Bracket design maximizes protection given to important components such as the piston, rotate motor, speed valve & hydraulic hoses to ensure a lasting crusher.

- Hardfacing process applied to wear parts.

| Okada OSC Crusher Series | ||||||||

| Model | OSC-35AV | OSC-70AV | OSC-135AV* | OSC-200AV* | OSC-360AV | OSC-500AV | OSC-650AV | |

| Operating Weight | kg | 280 | 650 | 1090 | 1790 | 3090 | 4800 | 5420 |

| Overall Length | mm | 1245 | 1580 | 1930 | 2190 | 2700 | 3090 | 3625 |

| Overall Height | mm | 705 | 960 | 1175 | 1410 | 1760 | 2135 | 2210 |

| Max Jaw Opening | mm | 430 | 600 | 720 | 860 | 1105 | 1417 | 1500 |

| Cutter blade length | mm | 90 | 100 | 150 | 150 | 180 | 215 | 215 |

| Crushing Force (At center) | kN | 305 | 450 | 600 | 880 | 1000 | 1115 | 1400 |

| Operating Pressure | Mpa | 25 | 28 | 28 | 32 | 32 | 32 | 32 |

| Suitable excavator Range | Ton | 3 - 5 | 6 - 9 | 10 - 16 | 18 - 25 | 30 - 45 | 40 - 100 | 50 - 100 |

* Electric or Permanent Magnet option available

| Model | ORC200V | |||||||

| Rotation Type | Hydraulic Rotation (HR) | |||||||

| Operating Weight | kg | 2050 | ||||||

| Overall Length | mm | 2300 | ||||||

| Overall Height | mm | 1518 | ||||||

| Max Jaw Opening | mm | 805 | ||||||

| Cutter blade length | mm | 180 | ||||||

| Crushing Force (At center) | kN | 900 | ||||||

| Operating Pressure | Mpa | 32 | ||||||

| Suitable excavator Range | Ton | 18 - 35 | ||||||